Laser Applications Conference – Panels

Information about invited speakers and accepted, contributed oral talks within each session will be available soon.

AI & ML in Material Processing

Organizer: Thomas Grünberger, Plasmo Industrietechnik GmbH, Austria

The session will provide an overview of the possibilities of AI and ML, including examples in the field of laser material processing. Attention will be drawn on added value in the field of data analytics in all forms - descriptive, diagnostic, predictive and prescriptive.

Brittle Materials Processing

Organizer: Qiongying Hu, Coherent Inc., USA

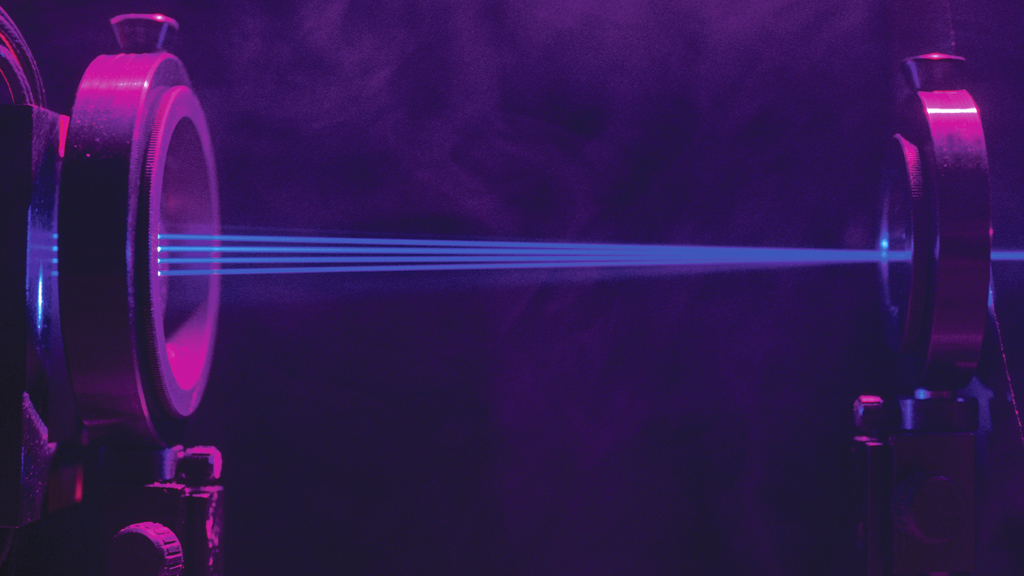

Brittle materials pose a significant challenge to mechanical machining. Lasers have a unique advantage in processing a variety of brittle materials as their wavelengths and pulse durations can be tailored to optimize the material interaction. Brittle materials such as glass, sapphire, silicon and SiC are increasingly benefitting from laser processing. Unique laser cutting, drilling and polishing methods are lowering the cost of machining these materials at unprecedented accuracy. Furthermore, lasers are finding increased adoption for annealing these brittle materials.

Fusion Energy

Organizer: Gabrielle Thomas, Menlo Systems GmbH, Germany

Fusion energy holds many promises for the future of clean energy, and in recent years enormous progress has been made towards fusion energy. In December 2022, scientists at the National Ignition Facility at the Lawrence Livermore National Laboratory in California (LLNL) managed to produce for the first time a nuclear fusion reaction that released more energy than it used. There is still more work to be done to reach a point where we have a long-term, sustainable source of fusion energy; this session will focus on some of the key ways in which laser technology is paving the way toward this goal.

Micro Nano Material Processing

Organizer: Ruth Houbertz, ThinkMade Engineering and Consulting, Germany

The processing of micro and nano structures is a continuously growing field due to its wide applicability. Laser micro and nano machining provided versatile processing technologies, providing access to many applications and novel product features. Compared to other structuring technologies, no masks are necessary to create the structures, which range from 2D via 2.5D to real 3D structures, using additive, subtractive, ablative processes or even a mix-and-match of the same with a freedom in design that is not feasible using other structuring techniques from the micro to the macro scale. Dependent on the kind of laser and the types of materials that are used in the processes, either functional surfaces or functional structures can be created on a micron down to the 100 nanometer scale and even below. A prominent feature is that the structures are not limited to micrometer size areas, but can be also scaled to square meters and beyond. Aside of surface-based submicron structuring, nanoparticles can be fabricated as well, which can be implemented in many applications.