About

31 October 2019

New Printer Creates Extremely Realistic Colorful Holograms

Technology offers high-speed, high-quality printing that could be useful for architecture models, fine art, exhibits and other applications

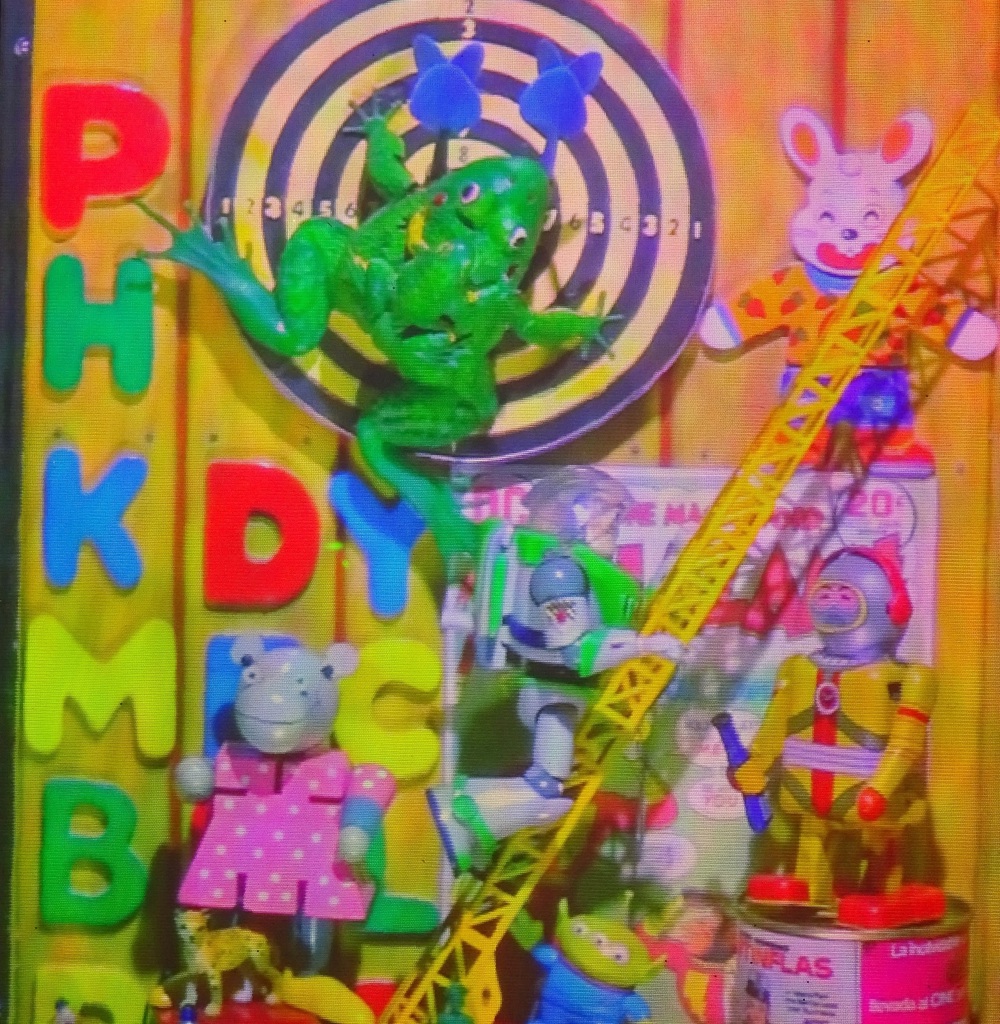

WASHINGTON — Researchers have developed a new printer that produces digital 3D holograms with an unprecedented level of detail and realistic color. The new printer could be used to make high-resolution color recreations of objects or scenes for museum displays, architectural models, fine art or advertisements that do not require glasses or special viewing aids.

Caption: Researchers developed a new system that prints holograms such as the one shown with an unprecedented level of detail and realistic color.

Credit: C Yves GENTET

“Our 15-year research project aimed to build a hologram printer with all the advantages of previous technologies while eliminating known drawbacks such as expensive lasers, slow printing speed, limited field of view and unsaturated colors,” said research team leader Yves Gentet from Ultimate Holography in France. “We accomplished this by creating the CHIMERA printer, which uses low-cost commercial lasers and high-speed printing to produce holograms with high-quality color that spans a large dynamic range.”

In The Optical Society (OSA) journal Applied Optics, the researchers describe the new printer, which creates holograms with wide fields of view and full parallax on a special photographic material they designed. Full parallax holograms reconstruct an object so that it is viewable in all directions, in this case with a field of view spanning 120 degrees.

The printer can create holograms from 3D computer generated models or from scans acquired with a dedicated scanner developed by the researchers. The high-quality holograms can even be used as masters to produce holographic copies.

Building a better printer

When developing the new hologram printer, the researchers carefully studied two previously developed holographic printer technologies to understand their advantages and drawbacks.

“The companies involved in developing the first two generations of printers eventually faced technical limitations and closed,” said Gentet. “Our small, self-funded group found that it was key to develop a highly sensitive photomaterial with a very fine grain rather than use a commercially available rigid material like previous systems.”

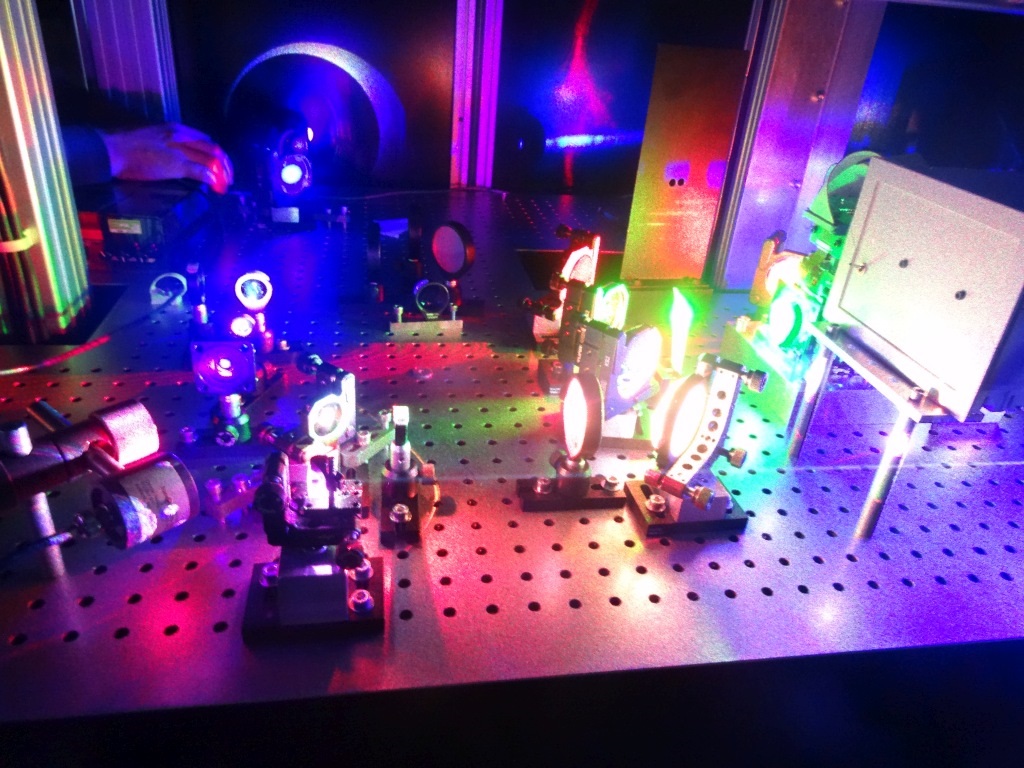

The CHIMERA printer uses red, green and blue low-power commercially available continuous wave lasers with shutters that adjust the exposure for each laser in a matter of milliseconds. The researchers also created a special anti-vibrating mechanical system to keep the holographic plate from moving during the recording.

Caption: The new printer uses low-power continuous wave lasers to create holograms on a highly sensitive photomaterial developed by the researchers.

Credit: C Yves GENTET

Holograms are created by recording small holographic elements known as hogels, one after another using three spatial light modulators and a custom designed full-color optical printing head that enables the 120-degree parallax. After printing, the holograms are developed in chemical baths and sealed for protection.

The hogel size can be toggled between 250 and 500 microns and the printing rate adjusted from 1 to 50 hertz (Hz). For example, if a hogel size of 250 microns is used, the maximum printing speed is 50 Hz. At this speed it would take 11 hours to print a hologram measuring 30 by 40 centimeters, about half of the time it would take using previous systems based on pulsed lasers.

High brightness and clarity

The researchers used the new technology to print holograms that measured up to 60 by 80 centimeters showing various color objects including toys, a butterfly and a museum object.

“The new system offers a much wider field of view, higher resolution and noticeably better color rendition and dynamic range than previous systems,” said Gentet. “The full-color holographic material we developed provides improved brightness and clarity while the low-power, continuous wave lasers make the system easy to use.”

The researchers say that as technology improves, especially 3D software, it may be possible to expand their hologram printing approach to medical or other advanced applications.

Paper: Y. Gentet, P. Gentet, “CHIMERA, a new holoprinter technology combining low-power continuous lasers and fast printing,” Applied Optics, 58, 34, G226-G230 (2019).

DOI: https://doi.org/10.1364/AO.58.00G226

About The Optical Society

The Optical Society (OSA) is dedicated to promoting the generation, application, archiving, and dissemination of knowledge in optics and photonics worldwide. Founded in 1916, it is the leading organization for scientists, engineers, business professionals, students, and others interested in the science of light. OSA’s renowned publications, meetings, online resources, and in-person activities fuel discoveries, shape real-life applications and accelerate scientific, technical, and educational achievement.

About Optical Materials Express

Optical Materials Express is an open-access journal focusing on the synthesis, processing and characterization of materials for applications in optics and photonics. It is published by Optica Publishing Group and emphasizes advances in novel optical materials, their properties, modeling, synthesis and fabrication techniques; how such materials contribute to novel optical behavior; and how they enable new or improved optical devices. The Editor-in-Chief is Andrea Alù from City University of New York, USA. For more information, visit Optical Materials Express.

Media Contact